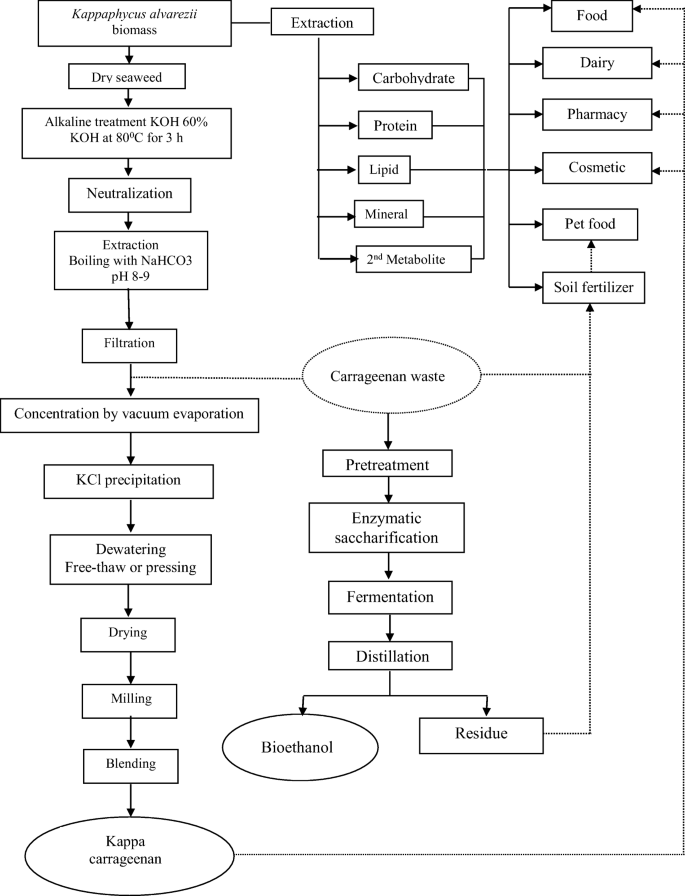

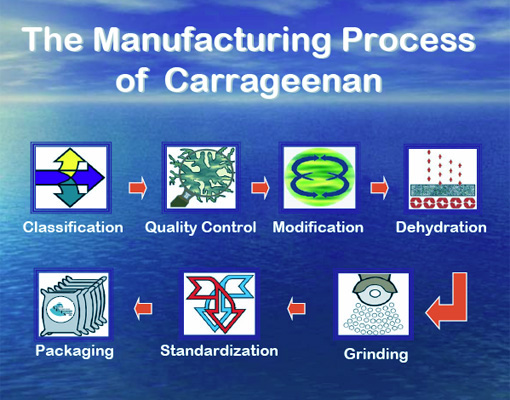

carrageenan production process

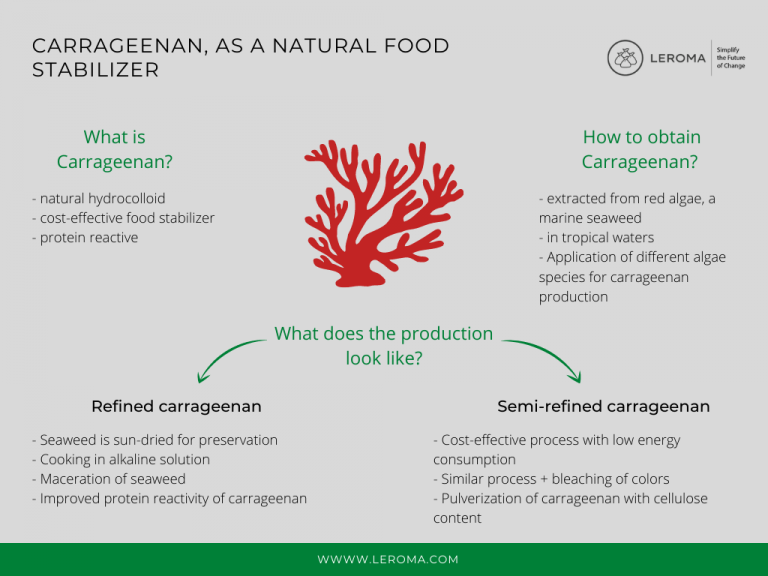

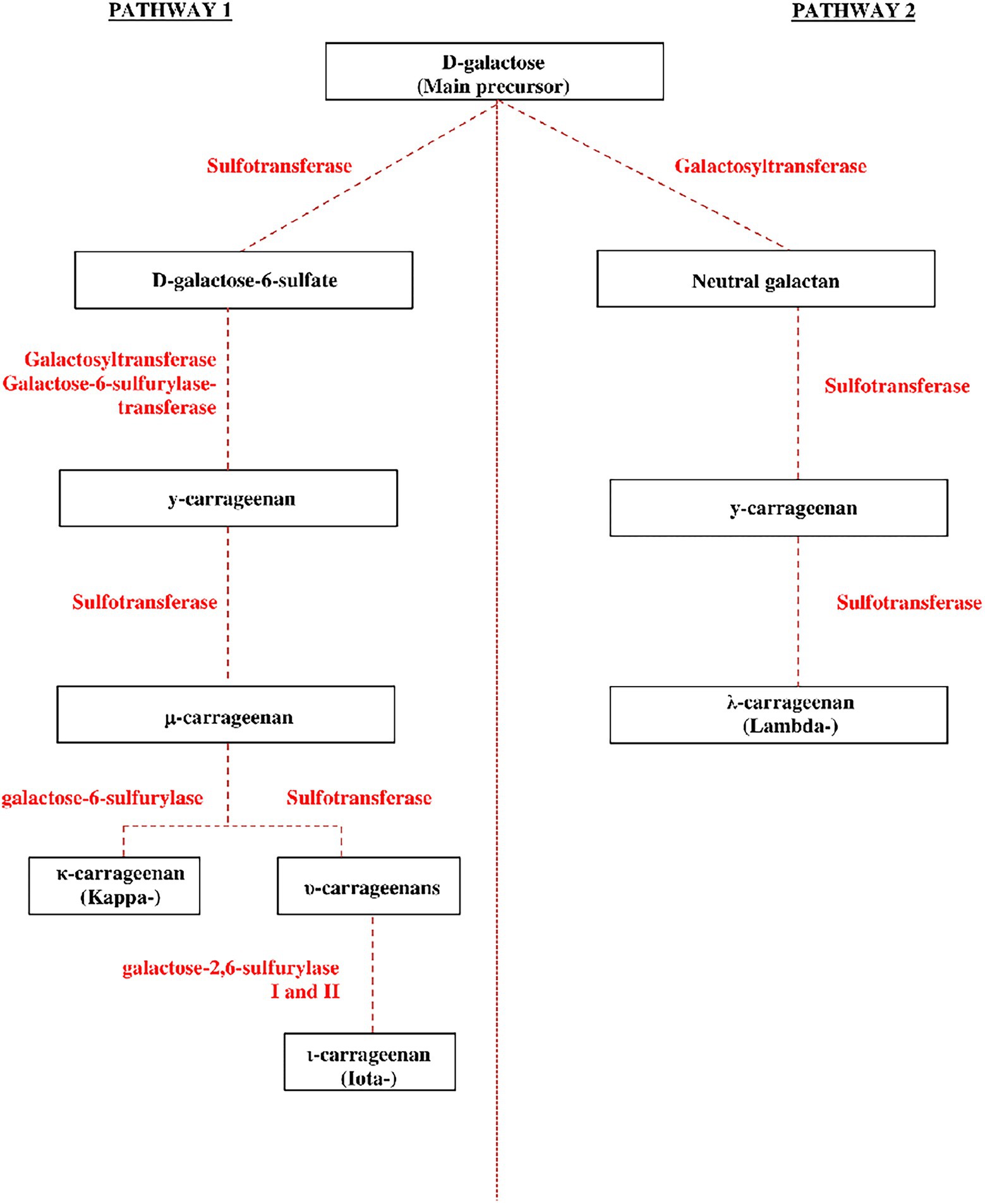

Carrageenan synthesis by the treatment of OH from red algae. Carrageenan also offers some in-process advantages because it has a comparatively low viscosity in solution before it gels.

Process Flow Sheet For Preparation Of Semi Refined Carrageenan Download Scientific Diagram

First process that the factory will do is the grinding process to make the raw material which is the kappa carrageenan itself becomes easier to be processed.

. In a flan product carrageenan will form the necessary gel structure control the basic product texture react with and stabilize the milk protein provide uniform stabilization and improve flavor release. KCl Precipitation or gel press. The use of carrageenan provides the following advantages in cheese production.

To do it the caraageenan factory will use freeze-thaw method which will pour the solution through small holes to be mixed with potassium chloride solution. Most of the carrageenan derivatives consider for cosmeceutical production and isolated from red seaweeds. For refined carrageenan there are three methods used in the industry.

This step is necessary to remove any foreign material such as sand salts sticks and any debris which may appear naturally with the seaweed. This will result in spaghetti like carrageenan which still needs to be washed using potassium chloride solution and pressed to eliminate the water content before being frozen. The first step in the production process is the cleaning and washing.

A basket of seaweed fronds is immersed and cooked in hot aqueous potassium hydroxide and then. Electricity Costs Table 4. A new process and product is semi-refined carrageenan.

Technical aspects of carrageenan manufacturing process of corrageenan process flow diagram commericial extraction of carrageenan the alcohol preparation extraction method. Carrageenan Production via Extraction. To ensure sustainable sourcing of our offer Cargill has established the Red Seaweed Promise.

Carrageenans or carrageenins are a family of natural linear sulfated polysaccharides that are extracted from red edible seaweeds. Slicing gratting melting hot viscosity quick setting gel. Alkali treatment and extraction After the seaweed has been cleaned it is heated with water containing an alkali for several hours.

Syndicated Analytics latest report titled Carrageenan Production Cost Analysis 2022-2027. Primarily wild-harvested genera such as chondrus furcellaria gigartina sarcothalia mazzaella iridaea mastocarpus and tichocarpus are also mainly produced as carrageenan raw materials. 04 Programs Shared Service Facilities SSF Project.

71 Carrageenan production methods 711 Refined carrageenan and filtered carrageenan. Refined carrageenan is the original carrageenan and until the late. Germany - based plant Q2 2022 From 149900 USD.

Production process for semi-refined carrageenan is always the same. The traditional process for the production of carrageenan is the alcohol precipitation process. Carrageenan is an important production used in the cosmetic industry because of its physical and functional ability and antioxidant activity.

The semi-refinedpes extraction method. Steam Costs Table 5. Semi-refined carrageenan SRC was the name given to the product first.

Producing countries include argentina canada chile denmark france japan mexico morocco portugal north korea south korea spain russia and the usa. Capital Investment Manufacturing Process. Raw Material Costs Table 3.

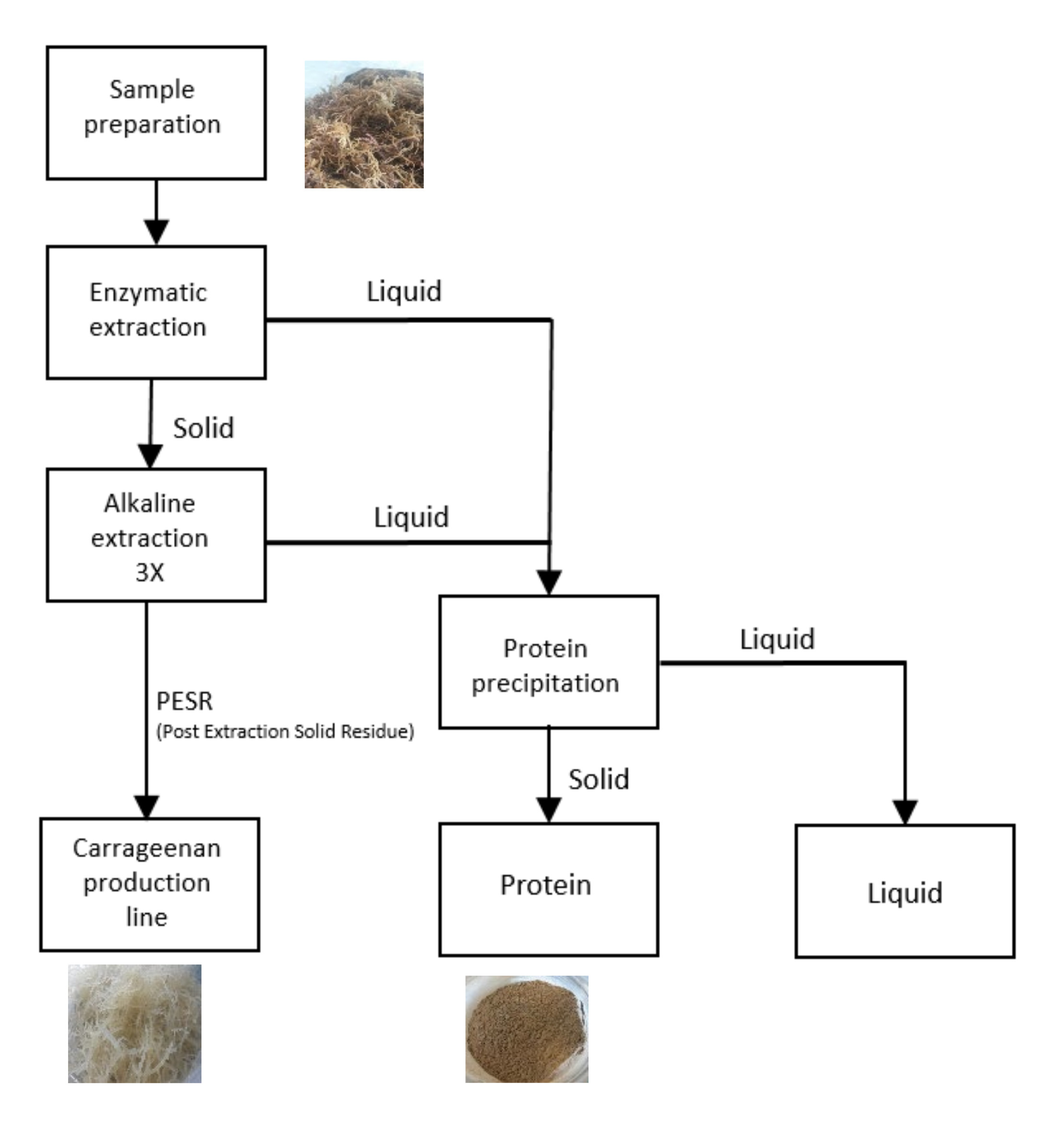

Cooking and washing the seaweed After sorting of the seaweed we process the seaweed based on the Good Manufacturing and Good Hygiene Practice. The production and manufacture of export products covers the productionmanufacture of non-traditional export products and with export requirement of at least 50 of its output if Filipino-owned or at least 70 if foreign-owned. The gel-press extraction method.

Semi-refined carrageenan at concentrations of 0 mgml 1 mgml 5 mgml and 10 mgml was incubated with blood of intact female WAG. In this process the extracted raw weed is first washed dried and chopped. Drum Drying Alcohol Precipitation and Gel Press.

There are four basic processes used for the production of carrageenan. Cargill offers one of the widest ranges of commercially available carrageenan employing proven production processes and using a large variety of different types of red seaweeds Rhodophyceae from the Gigartinales group. Process Water Costs Table 6.

Sequences in carrageenan manufacture lambda carrageenan lota carrageenan semi processsemi refined carrageenan. Then the sifting process which is to remove any sand that carried on the raw material accidentally. 712 Semi-refined carrageenan and seaweed flour.

This report presents a detailed cost analysis of carrageenan production from seaweed. Carrageenan in combination with other food ingredients provides multiple texture options. Reduce the risk of syneresis improving cheese quality and extending shelf life.

For the sake of convenience we will refer to these as. Production Process Selecting and sorting high quality seaweed Before we receive the seaweed from our farmers we test the raw material in our laboratory and sort and select the high quality seaweed. Of course washing process is done to completely remove other impurities.

Raw Material Requirements Table 2. This process which is distinguished by its low energy input uses Eucheuma cottonii as a raw material. The most well-known and still most important red seaweed used for manufacturing the hydrophilic colloids to produce carrageenan is Chondrus crispus which is a dark red parsley-like plant that grows attached to the rocks.

Cottonii is prepared by a method which superficially resembles that for French fried potatoes. Semi Refined Standard Method Refined by Drum Drying Refined by Alcohol Precipitation Refined by Gel Press Properties 1.

Sequential Acid And Enzymatic Hydrolysis Of Carrageenan Solid Waste For Bioethanol Production A Biorefinery Approach Springerlink

Leroma Carrageenan A Natural And Versatile Food Stabilizer

Frontiers Carrageenan From Kappaphycus Alvarezii Rhodophyta Solieriaceae Metabolism Structure Production And Application

Carrageenan Production Methods

Foods Free Full Text Multi Extraction And Quality Of Protein And Carrageenan From Commercial Spinosum Eucheuma Denticulatum Html

Carrageenan Foods Additives Is Carrageenan Safe

Carrageenan 101 Mcpi Carrageenan For The World

Proposed Carrageenan Biosynthesis Pathways Pathway 1 Download Scientific Diagram

Carrageenan Manufacturing Process Flow Chart Re Produced From Download Scientific Diagram

Re Evaluation Of Carrageenan E 407 And Processed Eucheuma Seaweed E 407a As Food Additives 2018 Efsa Journal Wiley Online Library

Pdf Extraction And Isolation Of Kappa Carrageenan From Red Seaweeds Semantic Scholar

Lecture Xviii Charged Ps S Carrageenan Agar Ppt Download

Characteristics Of Lactose Free Frozen Yogurt With K Carrageenan And Corn Starch As Stabilizers Journal Of Dairy Science

Conventional Extraction Method Of Refined Carrageenan Rc And Download Scientific Diagram

Carrageenan Manufacturing Process Flow Chart Re Produced From Download Scientific Diagram

5 Flow Chart Of Semi Refi Ned Carrageenan Production Where The Download Scientific Diagram

0 Response to "carrageenan production process"

Post a Comment